UV and IR equipment for Screen printing

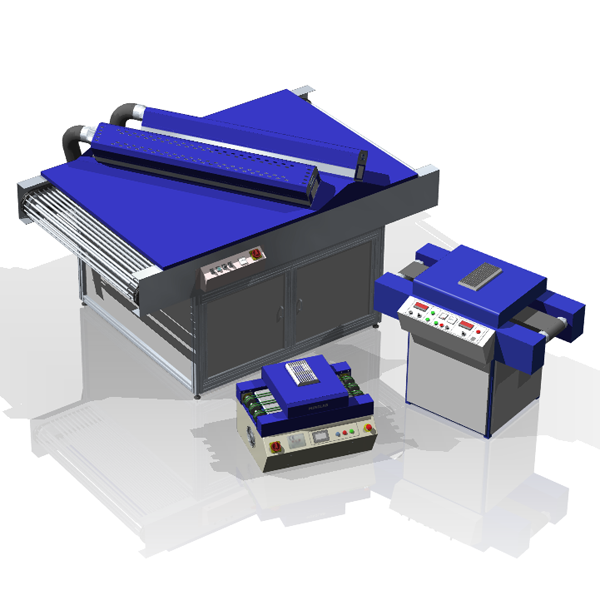

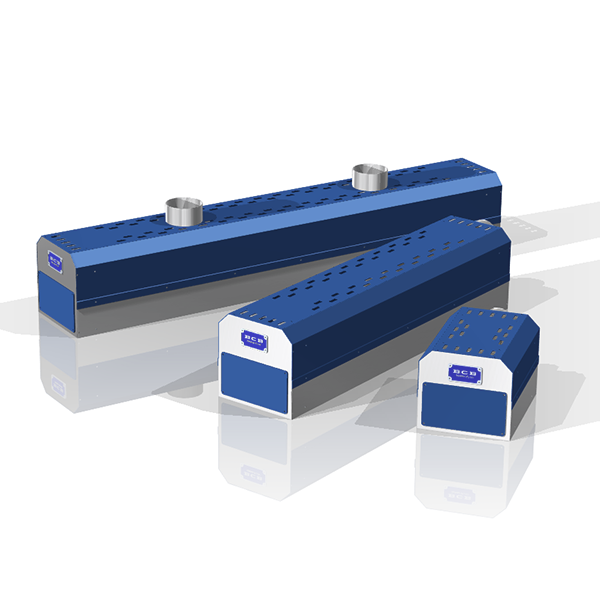

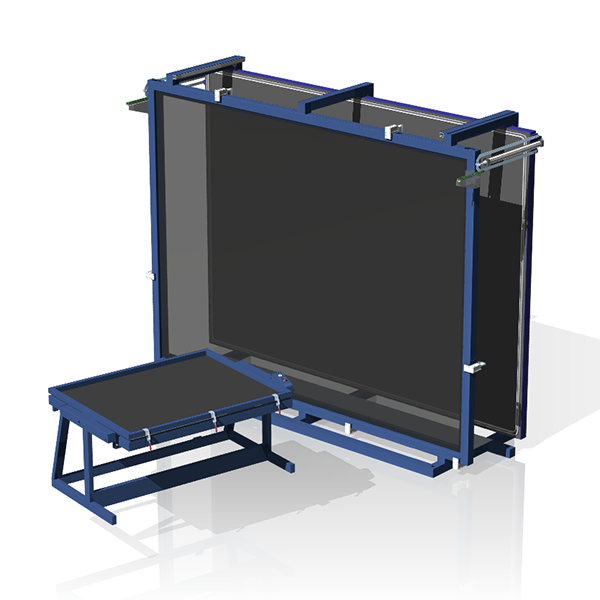

We manufacture all types of ultraviolet and infrared machinery for treatments in screen printing and other graphic arts. In addition, as our equipment is custom designed, we can adapt to virtually any existing silk-screen machine on the market. We can also make an independent autonomous system according to the requirements to be covered in each case:

- Flash IR equipment for screen printing carousels.

- UV bridges for adaptation to heat ovens.

- Ultraviolet ovens for decoration curing in fabrics, cardboard …

The use of UV and infrared technology in the silkscreen processes and graphic arts results in very high level products in any of its modalities:

- Infrared is used in the drying of traditional water or solvent based inks or varnishes. It is a fast, clean and very reliable method.

- Also the use of UV inks and varnishes allow some amazing brightness and textures, as well as being able to give volume to an image giving appearance of relief or depth. UV inks are very useful for their resistance to weathering in large format wall signs, for outdoor advertising, etc.

Ask us without obligation if you would like us to advise you on the most appropriate solution to your needs for drying or UV curing in serigraphy.